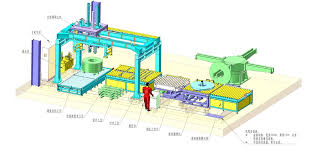

| Enquiry sheet for coil Packaging machine – Eye to Wall | ||

| Sr. No. | Description | Requirement |

| Wider coil / slit | ||

| 1 | Model | |

| 2 | Coil OD | 700-2000mm |

| 3 | Coil ID | 508-610mm |

| 4 | Coil Width | 25-1300mm |

| 5 | Coil Weight | 25MT (Max.) |

| 6 | Orientation of Coil – Entry | Eye to wall |

| 7 | Orientation of Coil – Exit | Eye to wall |

| 8 | Loading of coil | By Overhead crane / forklift |

| 9 | Unloading of Finished coil | By Overhead crane / forklift |

| 10 | Coil Temperature | 50˚C (Max.) |

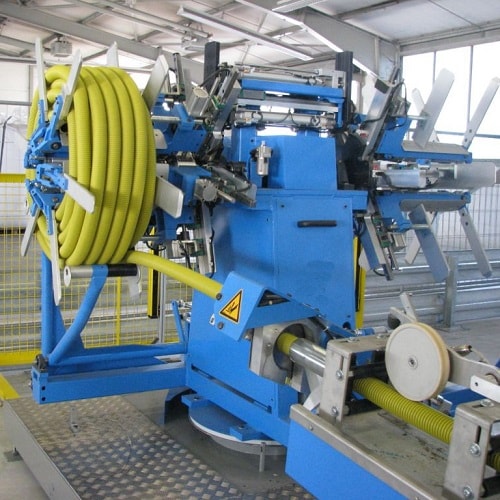

| 11 | Wrapping Material Data | |

| a | Type | HDPE, LDPE, Crepe paper, knit belt, Blue ploythene, bubble sheet |

| b | Double wrapping at a time | Required |

| c | Cutting Device | Automatic |

| d | Tension | Adjustable |

| e | Friction between wheels and ring | Adjustable |

| f | Level height of turning ring | Adjustable |

| 12 | For Main Spool for HDPE flim | PE / HDPE / PAPER / KNIT BELT |

| a | Thickness | 80gsm-140gsm |

| b | Roll OD | 250mm max. |

| c | Roll Width | 190mm +/- 5mm |

| d | Roll ID | 75mm +/-5mm |

| 13 | For 2nd spool for strech flim | LDPE / PVC / STRETCH FILM |

| a | Thickness | 50 microns – 80 microns |

| b | Roll Diameter | 230mm max. |

| c | Roll Width | 250mm +/- 5mm |

| d | Core Diameter | 75mm +/-5mm |

| 14 | Productivity / effective working houors | Min 10 Coils / Per Hour |

| 15 | Ring Speed | Supplier to Specify |

| 16 | Overlap rate | Supplier to Specify |

| 17 | Roller speed | Supplier to Specify |

| 18 | Working modes | Automatic & Manual – Both |

| 19 | Space required | Supplie to provide |

| 20 | Air / Pneumatic Supply | 4-4.5 kg/cm2 |

| 21 | List of required Equipments | |

| a | Wrapping Machine / Main engine of the machine + One Loading / unloading trolley with track etc + Weighing system and display | 1 set (Wrapping Machine + Two trolleys with track etc + One Weighing system and display) |

| b | Automatic Film cutting & release mechanism | 1 set |

| c | Packing material preparation system | 1 set |

| d | Complete Electricals | 1 set |

| e | Complete Hydraulic and pneumatics | 1 set, if any |

| f | Manuals and CDs etc | 1 set |

| g | Spare parts | As per supplier, recommendation for one year spare |

| 22 | Electrical Data | |

| a | Power Supply | 3 Phase, 415 VAC±5, 50 Hz |

| b | Control Voltage | 24VDC |

| c | Connected Power | As per supplier design |

| 23 | Make of major bought of items | |

| a | PLC | Siemens |

| b | Touch Screen | Siemens |

| c | Inverter | Siemens |

| d | Transducer | MTL/P&F/PHOENiX/Autonics |

| e | Switch brand | Schneider |

| f | Encoder | Omron |

| g | Gear-Motor | SEW EURO or NORD |

| h | Bearing | SKF |

| i | Load-cell | Mettler Toledo/HY (Germany) |

| j | Hydraulic Cylinder | |

| k | Pneumatic Cylinder | FESTO |

| l | Hydraulic Valve | |

| m | Pneumatic Valve | FESTO |

| n | LM guide | HIWIN |

| 24 | Total Equipment wt. | |

| 25 | Price basis | |

| 26 | Payment Terms | |

| 27 | Delivery | |

| 28 | Warranty | |

| 29 | Guaranteed Value | |

| a | Overlapping accuracy | 5% |

| b | Throughput | min 10 coils/hour(M/c start-stop) |

| 30 | Costing |